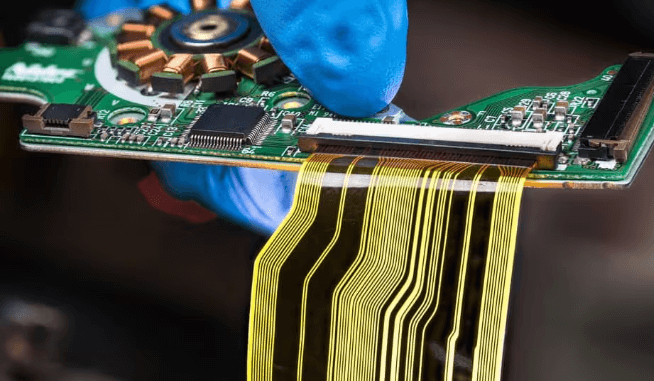

In today’s fast-paced electronics industry, flex circuits (also known as flexible printed circuits or FPCs) have become the backbone of compact, high-performance devices. From aerospace systems and medical instruments to smartphones and automotive electronics, these flexible boards enable design freedom and reliability where traditional rigid PCBs fall short.

However, the quality and durability of a flex circuit depend heavily on the manufacturer you choose. Not all manufacturers have the same level of expertise, equipment, or commitment to precision. Choosing the wrong partner can lead to costly design flaws, delays, or product failures.

To help you make an informed decision, here are the top 10 qualities to look for in a reliable flex circuit manufacturer.

1. Proven Industry Experience

The first indicator of a dependable manufacturer is industry experience. A company that has been in the business for years understands the nuances of flex circuit design, materials, and assembly challenges. Experienced manufacturers have refined their processes through continuous learning and innovation.

Look for manufacturers that have a proven track record serving industries like aerospace, medical, automotive, and telecommunications, where reliability is critical. Experience often translates to consistent quality and fewer production risks.

2. Advanced Manufacturing Capabilities

Modern flex circuits require precise processes and cutting-edge machinery. The manufacturer you choose should have state-of-the-art production capabilities including laser cutting, precision etching, automated optical inspection (AOI), and multilayer flex fabrication.

A manufacturer that invests in automation, cleanroom environments, and modern inspection technologies ensures consistency and accuracy in every circuit. This not only improves yield but also enhances long-term reliability.

3. Strong Design and Engineering Support

A good flex circuit manufacturer doesn’t just produce what you send; they collaborate with you during the design phase. Reliable partners offer Design for Manufacturability (DFM) and Design for Assembly (DFA) support, ensuring your circuit design is optimized for production and cost-efficiency.

Engineering teams with expertise in bending radius, layer stacking, impedance control, and material selection can help you avoid common design pitfalls. Early-stage collaboration can dramatically improve both performance and manufacturability.

4. Quality Certifications and Compliance

Quality assurance is non-negotiable in flex circuit manufacturing. Certifications such as ISO 9001, ISO 13485 (for medical), AS9100 (for aerospace), and UL indicate a manufacturer’s commitment to meeting international standards.

Additionally, compliance with RoHS, REACH, and other environmental regulations demonstrates responsible manufacturing practices. These certifications are proof that the manufacturer follows strict quality control protocols throughout production.

5. Material Expertise and Sourcing Integrity

Flex circuits require precise material selection including polyimide films, copper foils, adhesives, and coverlays to perform reliably under demanding conditions. A trusted manufacturer should have deep knowledge of material properties, including thermal stability, dielectric strength, and flexibility.

Moreover, they should partner with reputable suppliers to ensure consistent material quality. Avoid manufacturers that compromise on material integrity for cost savings, as this can lead to premature circuit failures.

6. Customization and Prototyping Capabilities

In many projects, off-the-shelf solutions don’t fit. That’s where custom flex circuit manufacturing becomes essential. The best manufacturers offer tailored solutions, from single- and double-sided circuits to multilayer and rigid-flex designs.

They should also provide rapid prototyping services, enabling quick testing and iteration before mass production. Fast turnaround on prototypes not only saves time but also allows for early performance validation and design refinement.

7. Transparent Communication and Project Management

Clear and consistent communication is one of the most underrated qualities in a manufacturing partner. A reliable flex circuit manufacturer maintains open communication channels, providing updates on production progress, timelines, and potential challenges.

Dedicated project managers ensure that engineering changes, delivery schedules, and quality checks are all well-coordinated. This level of transparency builds trust and minimizes unexpected surprises during production.

8. Rigorous Testing and Inspection Procedures

Testing is critical to ensuring that each flex circuit performs flawlessly in its intended environment. Leading manufacturers employ multiple levels of inspection and testing, such as:

- Electrical continuity and insulation resistance testing

- Thermal cycling and flex endurance tests

- Dimensional and visual inspections using AOI systems

These quality assurance steps detect defects early and guarantee product reliability, especially for applications that face vibration, temperature variation, and repeated flexing.

9. Scalability and Production Flexibility

Whether you need low-volume prototypes or high-volume mass production, the manufacturer should have the flexibility to scale according to your needs.

A dependable manufacturer can adjust their processes to meet different order sizes without compromising quality or delivery time. They should also maintain inventory control systems, lean manufacturing practices, and efficient logistics to handle varying production demands seamlessly.

10. Commitment to Continuous Improvement and Innovation

The electronics industry evolves rapidly, and a top-tier manufacturer evolves with it. Look for a company that invests in R&D, process improvement, and emerging technologies like additive manufacturing, high-density interconnect (HDI) flex, and hybrid materials.

A culture of innovation ensures you’re always receiving circuits built with the latest advancements in materials science and manufacturing techniques. Such manufacturers don’t just meet today’s requirements, they anticipate tomorrow’s challenges.

Bonus: Why Partnering with a Trusted Name Matters

Partnering with an experienced and dependable flex circuit manufacturer can make the difference between a successful product launch and costly redesigns. Manufacturers that combine engineering expertise, high-end production tools, and strict quality control deliver results that stand up to real-world demands.

Brands like Insight PCB, for instance, exemplify the value of combining decades of experience with modern technology and a commitment to excellence. By choosing such a partner, you ensure that your circuits are built to perform consistently, no matter the application.

Conclusion

Selecting the right flex circuit manufacturer is a strategic decision that affects every stage of your product’s lifecycle, from design and performance to cost and delivery. The most reliable manufacturers are those that emphasize experience, quality, transparency, and innovation above all else.

Whether you’re developing next-generation automotive sensors, wearable devices, or aerospace control systems, partnering with a trusted manufacturer ensures your circuits deliver unmatched performance and reliability.

In an industry where precision is everything, make sure your partner shares your standards for excellence. Companies like Insight PCB continue to prove that with the right expertise, technology, and commitment, flex circuits can help shape the future of electronics.